Our Machine Range

Baking Oven

We offer both manual and automatic loading options for our baking ovens, tailored to meet the specific requirements of our clients.

- Our baking ovens come in capacities ranging from 20 trays to 60 trays, allowing for production levels from 20,000 to 60,000 loaves per day.

- Crafted from high-quality materials such as superior-grade metals including M.S. (mild steel) and S.S. (stainless steel).

- Equipped with an advanced electrical control panel, powerful motors, suction switch, and gearbox for seamless operation.

- Our baking ovens boast high production capacities, ensuring efficient output to meet your baking needs.

- Designed to be fuel-efficient, helping you save on operating costs while maintaining optimal performance.

- Features a soundproof blower for reduced noise during operation.

- Versatile fuel options including diesel, LPG, or natural gas, providing flexibility to suit your preferences and operational setup

Swing Tray Final Proofer

Introducing our Swing Tray Final Proofer, meticulously crafted to elevate your baking process:

- Constructed from premium-grade metals, including M.S. (mild steel) and S.S. (stainless steel), ensuring durability and reliability.

- Features separated panels equipped with digital temperature and humidity meters, along with an auto final proofing timer, allowing for precise control and optimal proofing conditions.

- Enhanced automation capabilities streamline operations and improve efficiency.

- Equipped with hot-dip galvanized trays, providing a hygienic and sturdy surface for proofing.

- Boasts an insulated roof for consistent temperature regulation and energy efficiency.

- Utilizes 18g 202-grade stainless steel vertical panels for added strength and longevity.

- Powered by a robust 1.5HP motor coupled with a gearbox, ensuring smooth and reliable operation.

Flour Shifter with Elevator

Introducing our Flour Shifter with Elevator, featuring:

- Equipped with both single and double screw elevators for versatile operation.

- Includes a stainless steel sieve vibrator powered by two motors (1HP each) for efficient sifting.

- Comes with motor starters for easy operation.

- Capable of handling flour capacity up to 1500kg per hour.

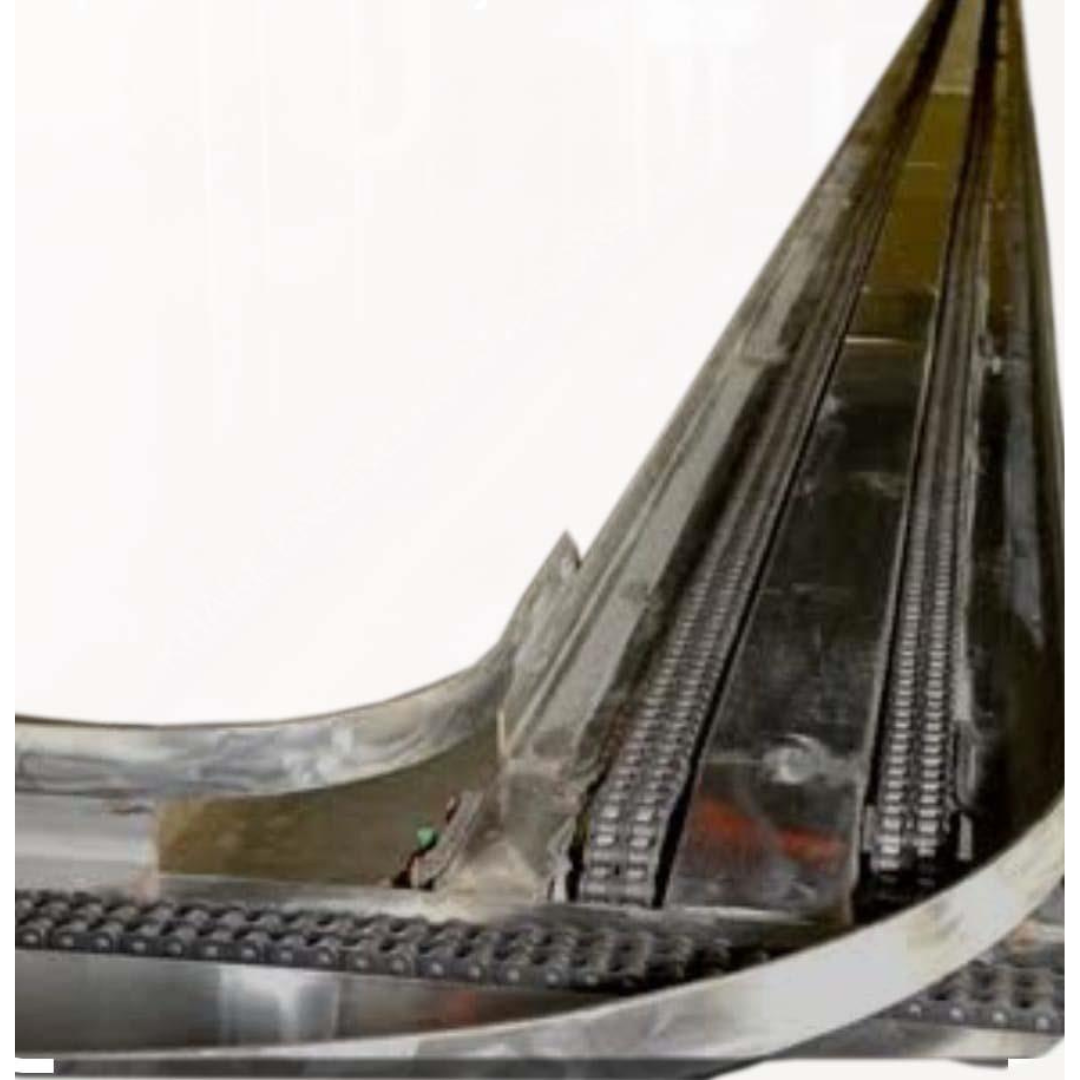

Duplex Chain Conveyor

Introducing our Duplex Chain Conveyor, engineered for reliable material handling:

- Constructed with S.S. sheet and pipe for durability and strength.

- Utilizes ¾” duplex chain to carry molds, ensuring secure transport.

- Connected with duplex sprockets for smooth and efficient operation.

- Equipped with a motor gear box assembly for controlled movement and precise positioning.

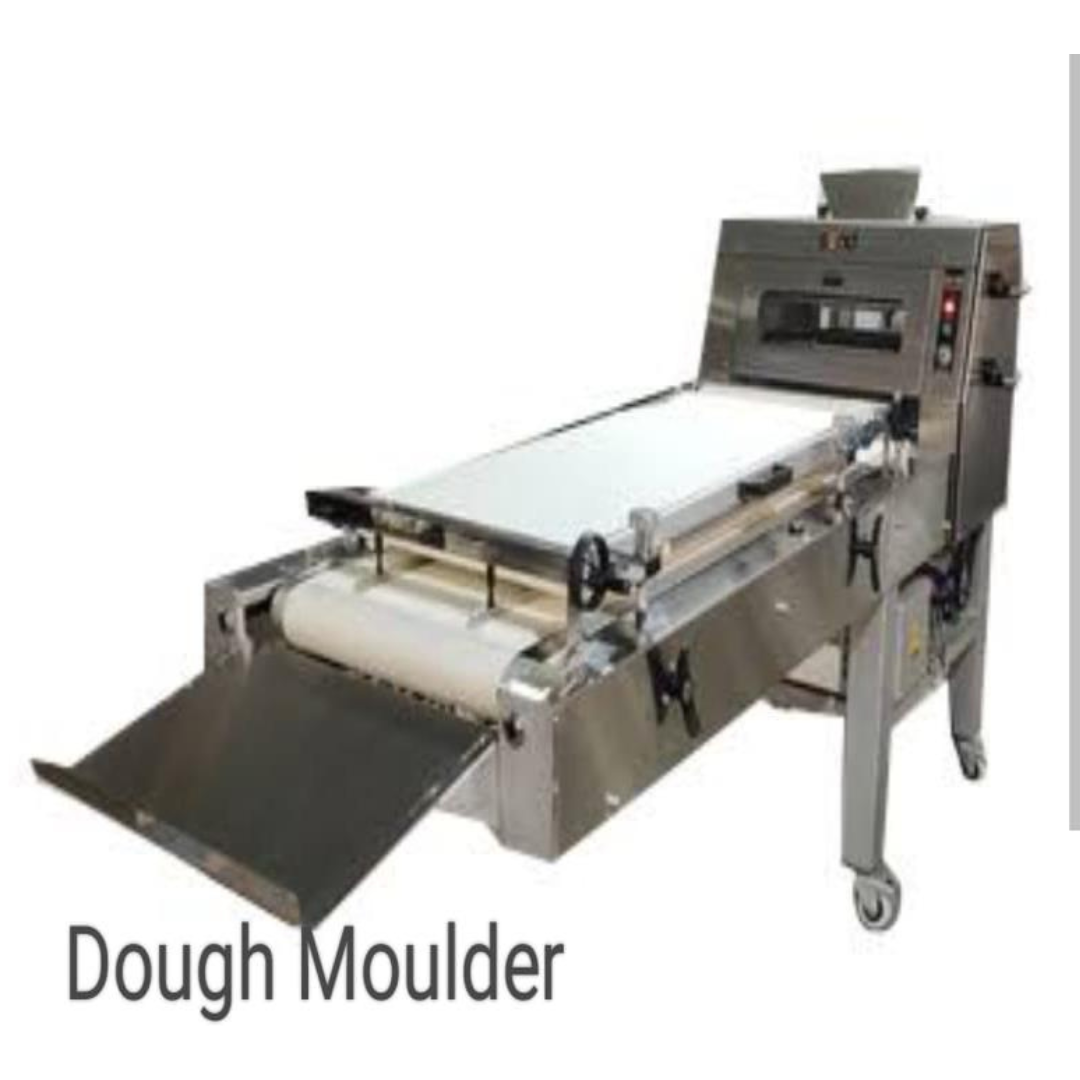

Dough Moulder

Introducing our Dough Moulder, engineered for precision and efficiency:

- Working capacity ranging from 150 to 1000gms, catering to diverse dough sizes.

- Powered by a 1.5 kW motor and helical gearbox (Italian), ensuring reliable performance.

- Features adjustable rollers made of precision materials such as Teflon or stainless steel.

- Equipped with three sets of sheeting rollers (total of 6 rollers) for thorough dough processing.

- Incorporates dough piece auto-centering guides for seamless shaping.

- Enhanced with stainless steel guards for safety and durability.

- Includes a reverse motion pressure board with a 0.37 kW motor, providing even texture and stretch during rolling.

- Conveyor belt made of polyester fabric with a width of 580mm, facilitating smooth dough transfer.

- Offers parallel height adjustment of the pressure board at the front and back for precise control.

- Features side openings of the pressure board for easy cleaning and maintenance.

- Machine dimensions: (Length x Breadth x Height) 2.8m x 1.0m x 1.5m.

- Weighs approximately 672 kg, ensuring stability during operation.

- Equipped with castor wheels for mobility and height adjustment options.

- Utilizes timing belt drive system, eliminating the need for lubrication or greasing.

- Designed with a split frame for easy belt replacement, ensuring minimal downtime.

Bread Cooling Tunnel

Introducing our Bread Cooling Tunnel, engineered for optimal cooling efficiency:

- Constructed with durable 18g 202 stainless steel sheet panels for longevity and reliability.

- Features inside pipe railing to facilitate the smooth movement of bread through the tunnel.

- Equipped with an exhaust-propelled fan to maintain consistent airflow and cooling conditions.

- Includes a trolley pusher and air washer device for enhanced functionality and cleanliness.

- Operates with a motor and gearbox for seamless reverse and forward movement.

- Utilizes a 30″ aluminum fan attached to a 3HP motor and 2HP pump for efficient air washing.

Bread Depanner System

Introducing our Bread Depanner System, engineered for efficiency and versatility:

- Capable of handling breads ranging from small to large sizes, accommodating a variety of pan dimensions both vertically and horizontally.

- Achieves speeds of up to 4000 breads per hour, maximizing productivity in your bakery.

- Powered electrically with a 13kw capacity, ensuring consistent and reliable performance.

- Features straight horizontal movement of the suction head, eliminating pivoting for smoother operation.

- Electrically controlled suction head movement with buttons for adjusting to various pan heights, enhancing convenience and flexibility.

- Easy-to-read mechanical indicator simplifies variety changes during operation.

- Designed with a zero-leak and wear-resistant suction head, eliminating the need for aluminum or nylon strips.

- Equipped with superior quality suction cups for optimal performance.

- Constructed with an all-stainless steel body for durability and hygiene.

- Incorporates a design without transmission sprockets and chains, minimizing maintenance requirements.

- Machine dimensions: (Length x Width x Height) (3.5m x 1.5m x 1.0m).

- Weight: Approximately 905 kg.

High Speed Mixer

Introducing our High-Speed Mixer, designed to meet your mixing needs efficiently:

- Comes with three stainless steel bowls, providing versatility and convenience in your mixing tasks.

- Powered by a robust 30+1 HP motor and gearbox combination, ensuring reliable performance and durability.

- Offers a swift mixing time of 2 to 2.5 minutes, allowing for quick and efficient blending of ingredients.

- Saves time and boosts production capacity, enhancing overall efficiency in your operations.

- Available in capacities of 20kg, 30kg, and 50kg, catering to various batch sizes and production requirements.

Dough Bowl Hoist

Introducing our Dough Bowl Hoist, engineered for seamless lifting operations:

- Equipped with a single post screw-driven mechanism, complemented by a motor, gearbox, and electric control box for efficient up-down operation.

- Delivers excellent lifting performance, ensuring smooth and precise movement of dough bowls.

- Designed for easy installation, simplifying setup and integration into your production line.

- Offers a lifting capacity of up to 6.5ft, providing ample reach for various applications.

- Available in capacities of 20kg, 30kg, and 50kg, catering to different batch sizes and production needs.

Bread Tin Cooler

Presenting our Bread Tin Cooler, equipped with:

- Ducting fabricated from stainless steel sheet and seamlessly connected to the conveyor.

- Integrated with air handling units (AHU) to ensure efficient cooling.

Collection Table

- SS Top rotating table completed with 1 HP motor.

- Gear box and motor starter.

Dough Divider (Volumetric) 2, 3, 4, 5 Poket

- Uniform division with equal weight.

- Easy to maintain.

- Equipped with high quality motor A C drives.

- Dough weight cutting range 40g – 100g.

- Hopper capacity 90 kg- 120kg.

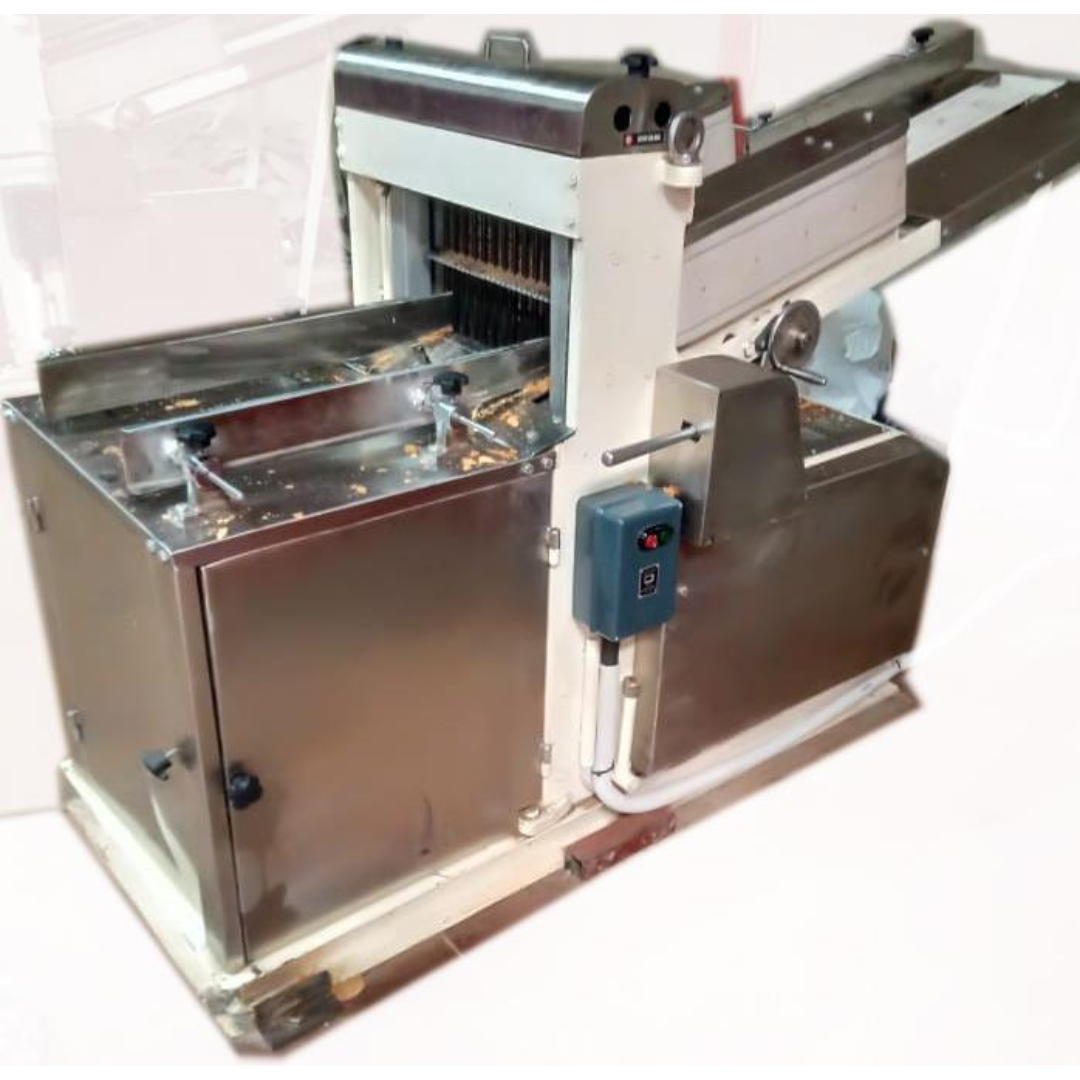

Bread Slicer

- Mounted with 19mm thick plate & 4” channel base.

- Capacity 1800 to 2000 bread/hour.

- Complete with crank case connecting rod & piston.

- 3 HP motor & gear box.

- Aluminium frame body covered with SS sheet 18g.

Cooling Trolley

Manufactured by superior quality steel (M.S. & S.S.) as per client requirements.

Dough Rounder

Introducing our Dough Rounder, designed to streamline your dough processing:

- Compatible with dough cutting sizes from dividers, ensuring uniformity in your dough products.

- Features a CL cone over integrated worm gear design for efficient rounding.

- Speed matched to synchronize seamlessly with dough dividers, optimizing production flow.

- Powered by a 0.75 kW electric motor for reliable performance.

- Dimensions: (Length x Breadth x Height) 1.8m x 0.53m x 2.0m.

- Weight: Approximately 770 kgs.

Dough Transfer Conveyor

- Shuttle dough from rounder to moulder.

- Resting time and length shall be given as per dough.

- Polyester fabric conveyor belt with indexing guides.

- All stainless steel structure.

- Adjustable height.

- Electric – 0.37kw geared motor.

- Basic dimensions – (L*B*H)(1.8*0.53*2.0) meters.

- Weight – 175 kgs.

Spiral Mixer

Introducing our Spiral Mixer, crafted from premium-grade steel for exceptional durability and performance.

- Features an automatic electric panel for convenient operation and control.

- Equipped with a direct water and ice inlet during mixing, ensuring precise temperature regulation and consistent dough quality.

- Available in capacities of 30 kg, 50 kg, and 80 kg, catering to various batch sizes and production needs.

Water Measuring Tank

Introducing our Water Measuring Tank, designed for accurate water measurement:

- Crafted entirely from stainless steel for durability and hygiene.

- Features 50mm insulation with stainless steel cladding for temperature retention.

- Equipped with a digital thermometer for precise temperature monitoring.

- Includes a calibrated scale for accurate water measurement.

- Comes with a gauge glass for visual indication of water level.

- Features a 40mm stainless steel outlet pipe and ball valve for controlled water discharge.

Proofing Chamber

Introducing our Proofing Chamber, designed for precise dough proofing:

- Crafted from SS 304 puff panels, ensuring durability and insulation for consistent proofing conditions.

- Features a fixed door for easy access and enhanced temperature control.

- Equipped with inside pipe railing to facilitate the smooth movement of trays or racks.

- Includes a steam generation system to create the optimal environment for dough fermentation and rising.